Hygiene lighting

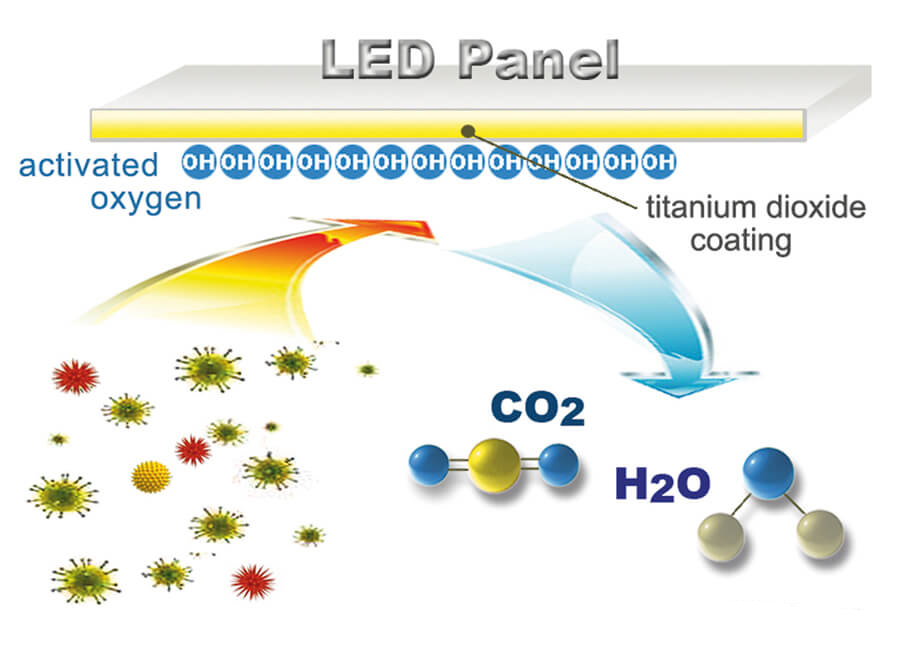

The prerequisite for good and sustainable photocatalysis is light. Perfect lighting conditions can now be achieved with new LED luminaires and lamps. Therefore, the coating of luminaire covers of all kinds is a good idea for the air purification and hygienisation of interior spaces, since on the surface of the luminaire there is most of the light energy in the room.

Coated lamps clean the air in a very effective way. The reactive oxygen species generated on the surface of the luminaire are capable of effectively removing odors, nicotine, cooking and toilet odors as well as viruses, germs and bacteria which can be transmitted through the air and come into contact with the luminaire surface.

Infections from the air

The droplet infection and the path of infection through the air are an integral part of the direct transmission pathway of pathogens of various kinds.

Particularly dangerous are so-called "droplet cores", which often measure only 5 μm and can travel long distances over the air. This is referred to as an aerogenic transmission. A good example is here the Mycobacterium tuberculosis, the causative agent of tuberculosis, which is transmitted chiefly in this way.

Pathogens transmitted through the air reach the mucous membranes of the upper respiratory tract and multiply there. Particularly during the cold season, flu-like infections are often transmitted along this path.

The coating of lamps

The coating of luminaire surfaces places high demands on the binding system and the correct processing of the coating products since surfaces such as PMMA and polycarbonate are very hydrophobic and have to be prepared for a permanent coating. For the crosslinking, drying and curing of these special coating systems, various integral process steps with IR and UV irradiation are required. For quality assurance, the luminaire and cover is only coated on modern PHOTOKAT production plants in Germany.

Faceplates

For simple retrofitting of existing lighting systems (for example, grid lights), we supply coated front panels for insertion into the ceiling grid or retrofitted into existing luminaires. The front panels are available in all standard dimensions and on request also in individual special formats.

The economy

Often the energy efficient replacement of existing lighting systems (e.g., T5 lights) is not economical. Here the retrofit of blends is a perfect solution. The blinds are simply inserted into the ceiling grid under the existing louvre. As a rule, fastening is not required as the overhead light reliably secures the lens.

The active principle

A coated ceiling light (60 x 60 cm, 5000 lumens) completely breaks down the smoke of a cigarette (23 mg organic material!) In 75 minutes to carbon dioxide, water and safe nitrates.

The advantages in overview:

- Neutralization of nasty smells and nicotine

- Elimination of harmful gases (e.g., formaldehyde)

- Broadband hygienisation of the room air

- Unlimited effectiveness of the coated luminaire

- Decomposition of germs and endotoxins on contact

- Absolutely safe in operation and application

- Coating is colorless and odorless

- Cost savings due to photocatalytic self-cleaning of the luminaire

- Technology is widely tested and certified

Downloads

For more information please refer to our Lightning Broschure (PDF).